ANTI-SLIP AND DIRT- PROOF SOLUTIONS

in U.S.A. SureStep is EuroStepTM+7 (495) 517-00-63

9:00 – 18:00 MSK

Instruction

Figure 3

Attention!

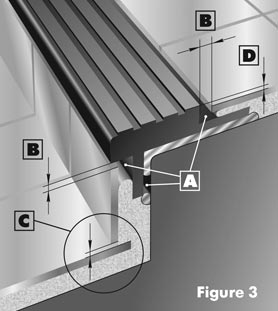

EuroStepTM experts caution you to avoid certain serious application mistakes that could result in a material reduction in the profile's effectiveness.A. DON'T leave any voids under tiles or either above or below fitting ledges.****

B. DON'T leave any gaps where tiles abut the profile. Any grout used to fill in such gaps will crumble out.

C. DON'T alter the sequence of mounting vertical (5) before horizontal tiles (7).*****

D. To avoid retaining water on steps, mount the horizontal tile flush with the surface of the profile's working element (1.1) or slightly higher, but never lower. For the same reason, EuroStepTM experts provide their steps with a slight frontal and longitudinal inclination.

Notes

* The quick-setting adhesive must be water- and frost-resistant. EuroStepTM experts recommend the following tile adhesives, each of which requires a setting time of three hours: "Quickfix" by the Danish firm ALFIX and "Granirapid" by the multinational concern MAPEI. While the use of other tile adhesives is acceptable, it is necessary to increase their curing times from three to twenty-four hours.** If abutting ends are pressed against each other, the profiles may shift before the adhesive sets due to the resulting stress.

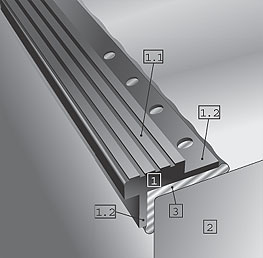

*** The tiles are laid on top of the profile's fitting ledges (1.2), which are about five (5) mm thick, so that the profile's working element (1.1) and tile surface are flush with each other. To achieve this result, given a tile thickness of eight (8) mm, the adhesive coating (8) between the tile and the underlying concrete step should be at least ten (10) mm thick. However, the recommended maximum coating thickness for most tile adhesives is less, five mm, as a thicker coating tends to crack during curing.

This problem could be resolved, conventionally, by first cementing the rubber profile onto the step surface and then applying a level layer of mortar over the fitting ledges so that they are firmly embedded within the mortar. After this layer has completely hardened, the tiles are then attached on top of it with a thin coat of adhesive. Such a procedure, however, greatly lengthens the tiling process by several days or even weeks, depending on the mortar used.

A better solution is to smooth out the step surfaces at the same time the tiles are attached. To do so, EuroStepTM experts recommend using the adhesive "Kerafloor" by MAPEI. This water- and frost-resistant adhesive is specially designed for both cementing tiles and smoothing out the surfaces to which they are attached. The recommended maximum thickness for the adhesive coating is fifteen (15) mm and is applied to both the step surface and back side of the tile (in which case, a toothed putty knife, e.g., 5 x 5 mm, is used).

People, in effort to save money, might be tempted to use a cheaper, common brand of adhesive such as "Atlas Plus" from Poland or apply a much thinner layer of adhesive than appropriate to the back sides of tiles. In addition, they may even attempt to lay a tile smeared with adhesive onto freshly smoothed-out mortar before the latter has properly set. While stairs thus treated may occasionally operate trouble-free for over a year, such shortcuts are risky and ill-advised. Consequently, it is always worth remembering that the quality of the workmanship is as important as that of the materials employed.

**** The level adhesive coating must completely cover the fitting ledges (1.2). The risk of tile failure increases under increased loads or impact stresses whenever the back surface of a tile is in direct contact with a fitting ledge (that is, without its intervening layer of adhesive) and, especially, whenever there are any voids either above or below the fitting ledge.

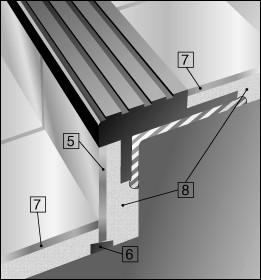

***** The tile (5) is an important load-bearing element and supports the front overhanging part of the rubber profile from below. The weight of a person stepping onto the front edge of the soft profile is borne by the vertical tile (5) tending to shift it downward. For this reason, it should not be mounted as shown in Figure 3.

If, instead, a vertical tile is mounted after and above the horizontal tile immediately below it, a gap will inevitably form between the top edge of the vertical tile and the profile. The vertical tile (5) will remain fixed only because of the adhesive coating attaching it to the stair riser.

In order to prevent the vertical tile (5) from breaking off due to the high vertical load, it is necessary to support its lower edge. This is achieved by following the instructions described in the section Setting Tiles. Move the vertical tile (5) upwards along the fresh adhesive coating until its upper edge is set against the profile. Fill the small gap (one to two mm) formed between the lower edge of the vertical tile and the horizontal surface of the step with several small supportive wedges (6) made of tile fragments. Next, apply a level adhesive layer along the horizontal surface of the step and then attach a horizontal tile (7) onto it. The lower edge of the vertical tile (5) will be safely walled in together with the wedges (6) supporting it.